4 Main Types of Flat Glass Suitable for Robotic Automation

Flat glass is essential in industries like construction and electronics, but glass handling presents challenges—especially as glass becomes larger and more specialized. Traditional manual methods struggle with precision, speed, and most importantly, safety.

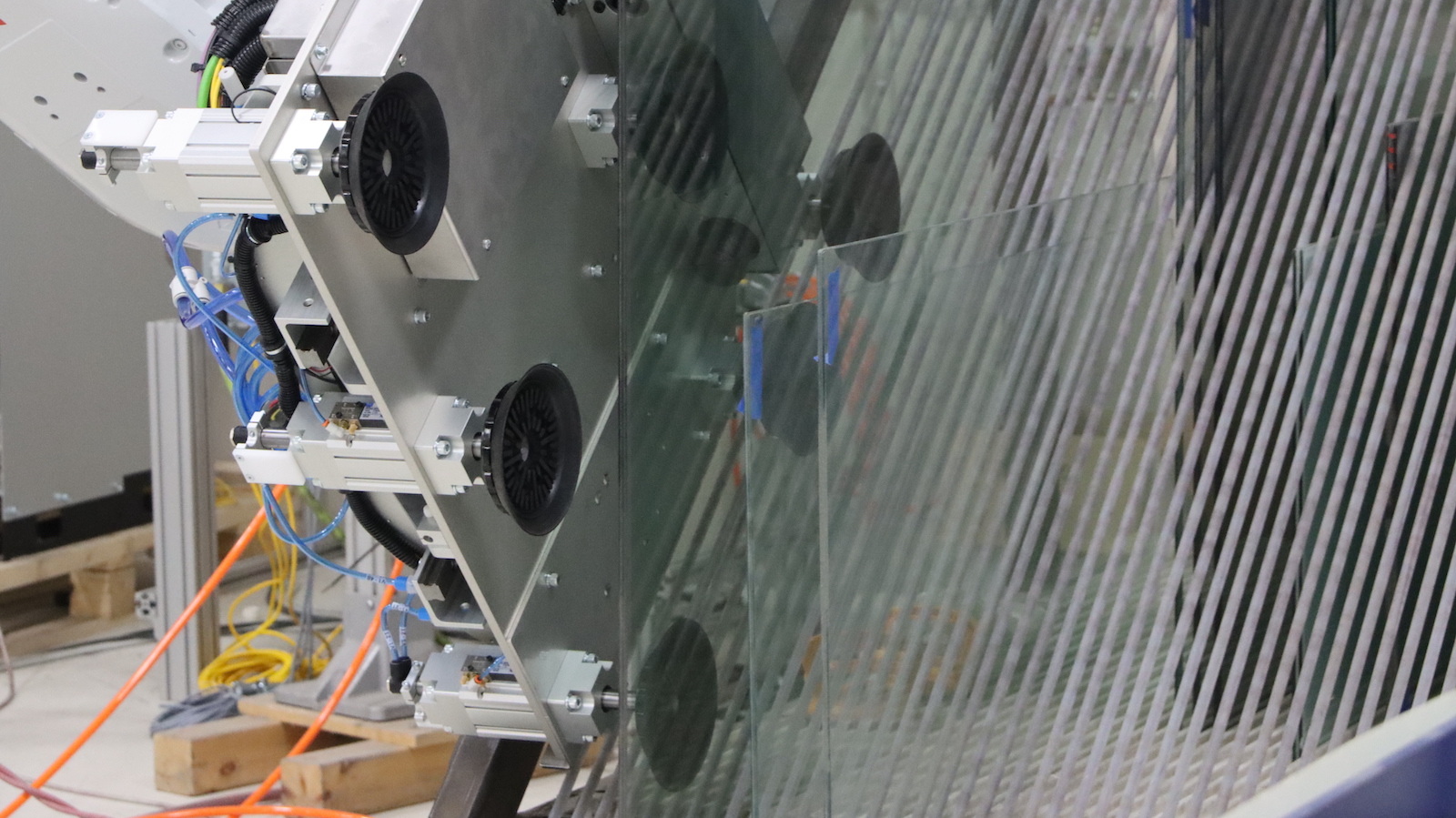

Advanced robotic pick-and-place systems, vacuum grippers, and vision-guided technology are minimizing breakage, improving efficiency, and ensuring precise movement of these delicate materials.

But the types of glass are wide-ranging. Here, we’ll explore different types of flat glass and the challenges of optimizing manufacturing, improving safety, and improving production. Let’s dive in.

VIDEO: See Glass Automation in Action

1. Float Glass

As its name suggests, float glass is made by pouring or “floating” molten glass onto a bath of molten tin. The top surface is called the air side, which is polished with fire. The bottom surface that comes into contact with the molten metal is called the tin side, which is unpolished. It is slowly cooled to become annealed glass, and then trimmed. The process creates a smooth, uniform surface that is distortion-free. Without further treatment, however, it is extremely fragile.

Common Uses of Float Glass

- The base for most other types of flat glass products

- Windows and glass doors

- Mirrors

Important Note: Robotic handling of fragile float glass requires extreme care. Since the annealed side is not polished, it should only be handled by touching the tin side. QComp has developed safe robotic solutions that pick glass through a conveyor system without marring the annealed side prior to the finishing process.

RELATED: Optimizing Glass Line Load & Unload With Robotics

2. Tempered Glass

Tempered glass is a type of safety glass that is heat-treated, undergoing a process of extreme heating followed by rapid cooling. This process increases its strength and durability, making it up to five times stronger than regular glass. When broken, tempered glass shatters into thousands of small, blunt-edged pieces instead of sharp shards, reducing injury risk.

Common Uses of Tempered Glass

- Building facades

- Shower doors

- Automotive side and rear windows

- Glass tabletops

- Oven doors, cooktops, refrigerator shelves, appliances

- Smartphone and tablet screens

3. Laminated Glass

Laminated glass is another type of strong glass that’s made by bonding two or more layers with an interlayer, often thermoplastic polyurethane (TPU), polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA). The special technique reduces shattering by keeping glass fragments adhered to the interlayer upon impact, improving safety. It can also provide sound insulation, UV protection, and enhanced security against break-ins.

Common Uses of Laminated Glass

- Vehicle windshields

- Hurricane-resistant windows and skylights

- Glass floors, walls, and railings

- Bank teller windows and bulletproof glass

4. Insulated Glass

Insulated glass, sometimes referred to as double- or triple-glazed glass, is a system of two or more panes of glass separated by a spacer. An inert gas — typically argon or krypton — fills the space between the panes. Common names include Low-E, Low-U, or thermal because the final product is highly energy efficient. The design also reduces noise and prevents condensation.

Common Uses of Insulated Glass

- Energy-efficient windows and skylights

- Glass doors

- Curtain walls and facades on high-rise buildings

- Refrigerated display cases

- Soundproof studio windows

Robotic Solutions for Flat Glass Handling

Regardless of the type of glass, a major challenge in glass handling is its fragility and varying sizes and configurations. Once produced, glass panels can be paper thin up to a half-inch thick and can range from less than a foot in diameter to as large as 8-feet x 12.5-feet. As a result, weights can range from ounces to more than 1,200 pounds.

QComp has mastered flat glass handling of all sizes — from the float plants to coating and tempering, and insulated and laminated glass — to the assembly and packing processes. This includes picking units from the manufacturing and cutting lines and placing them onto racks or picking glass from various rack types and loading lines for processing or assembly.

To achieve these complex tasks, QComp uses a combination of advanced robotics, specialized end-of-arm tooling, precision cable management, vision-picking technologies, and expert programming to integrate our solutions into your production processes.

The increased efficiency and quality are only surpassed by the reduction in injury-related incidents and breakage. Discover how our systems achieve these kinds of results in our glass automation guide, Improve Safety & Efficiency in Glass Manufacturing with Robotics. Simply click below for your free copy, and contact us to talk through your challenges.

Share this

You May Also Like

Cable Management in Glass Line Automation: An Overlooked Necessity

Learn how QComp and BizLink tackle cable durability, uptime, and safety challenges in glass robotic automation, redefining efficiency in glass manufacturing lines.

Automation Challenge: Glass Industry Harp Rack Loading

Learn how QComp’s innovative harp rack unloading automation improves glass industry safety, reduces risks, and boosts precision and productivity.

The Automation Advantage: Combat Labor Shortages and Win the Talent War

Discover how automation can help manufacturers tackle labor shortages, improve safety, and achieve a positive ROI in this insightful blog post conversation between industry experts.