Robotic Case Packing

Any Shape, Size & Material Without Sacrificing Throughput

Complex Material Handling Challenge? We’ve Got You Covered

QComp provides customized robotic case-packing solutions that are tailored to meet the unique requirements of your application. Our in-house end-of-arm tool design capabilities combined with vision-guided robotics allow for optimized top-load case pack configurations for a wide range of products and industries. Expect exceptional ROI with our flexible designs that help future-proof your investment as your product and market needs evolve.

QComp offers comprehensive system integrations that go beyond just case packing. We integrate with your upstream machinery and provide automated pre-case pack modules that bundle, kit, band, and wrap products to enhance the versatility of your automated production processes. We also develop systems that:

- Build gaylords

- Erect cases

- Feed multiple pallet varieties

- Weigh, seal, label, flow, and shrink wrap

Case Packing Solutions

Achieve Speed & Precision

Multi-Robot Case Packer

Compact and scalable in-line case packing marries vision-guided product tracking to pack items into shipping cases at a rate of 150 per minute or more.

Robotic Solo Case Packer

Compact and portable robotic solo case packer cells place individual products into shipping cases or containers at a rate of up to 30 layer picks per minute.

Washdown Case Packer

Meet strict hygiene standards while ensuring your equipment stands up to harsh environments with QComp's solo case packing cell, available in a full wash-down configuration.

Dual Case Packer

A dual case packer cell robotic packing system individually packs up to 150 products per minute into shipping cases or containers and includes a case erector, former, and case sealer.

Cobot Palletizer

Collaborative robotic technologies find the balance between safety and productivity while ensuring the appropriate cobot application and deployment. We provide training to further enhance worker safety.

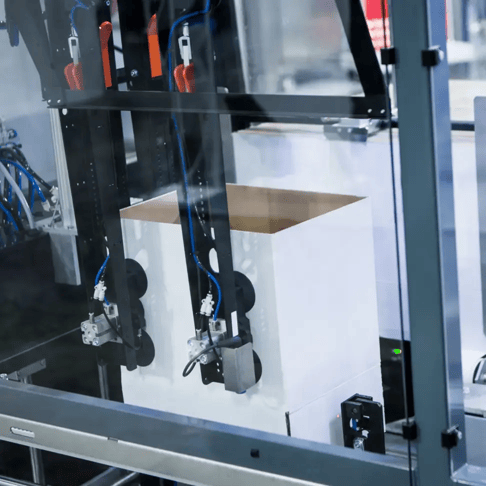

Case Packer with Carton Forming

Carton blanks can be picked, formed, glued, filled, and sealed in a continuous process to reduce manufacturing footprints and eliminate inter-process material handling.