Innovative Robotics Solutions

Solving Complex Material Handling Challenges

We’re Up for the Challenge

There are a lot of robotics integrators that can solve the easy stuff. Pick up a box and put it down? Not a problem. But what about those difficult material handling applications that you just can’t seem to find a solution for? We’ve got you covered there, too. Explore our success stories below and connect with our experienced team to talk about our proven solutions.

A lot of people can sell you a robot. We don't want that. We want people who deliver a full-line solution.

Jeff L.

Sr. Principle Engineer, Food Manufacturer

QComp’s Proven Solutions

Explore our specialty solutions below. Been scratching your head about another type of material handling challenge? Let us help.

Modular Picking Solutions

Whether picking multiple SKUs or changing recipes on the fly, QComp’s innovative picking solutions can keep you up and running to enhance productivity and optimize labor. Our tailor-made automation solutions combine state-of-the-art robotics technologies with engineering and programming expertise to meet your critical application needs.

- Specializing in pouch packers, lid applicators, cartoning, and tray-filling cells

- Leveraging Delta, SCARA, 6-Axis and other industrial robots or cobots

- Reduce parts inventory and maintenance-related costs

- Suitable for clean rooms and harsh wash-down environments

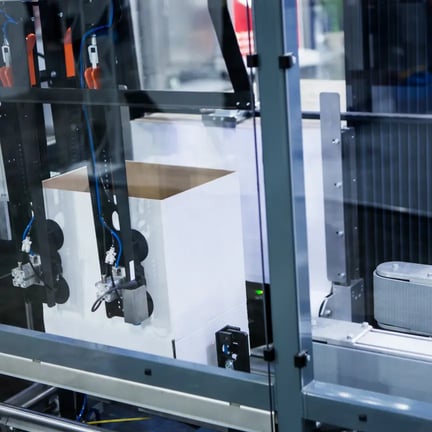

Case Packing

Trying to pack unusual shapes, sizes, or materials? Our scalable automation solutions are designed in-house and tailored to meet your complex needs without sacrificing throughput. Rely on QComp’s expertise to case pack, bundle, kit, band, and wrap products. Our systems can also build gaylords, erect cases, feed multiple pallet varieties, weigh, seal, label, flow, and shrink wrap. Just some of our solutions include:

- Multi-robot case packers

- Robotic solo case packers

- Washdown case packers

- Dual case packers

- Case packers with carton forming

Palletizing

From simple to complex, QComp’s innovators design vision-guided robotics and collaborative systems to guarantee high-speed palletizing without sacrificing throughput or quality. Some of our solutions include robotic palletizing of bottles, bags, and other products with unusual shapes and sizes, including fragile or boxed products with or without slip sheets. Our experts help ensure that ancillary equipment is integrated, from case erectors and sealers to slip sheet dispensers, pallet dispensers, and labelers.

- Compact palletizers

- Bag palletizers—up to 20 bags per minute

- Specialty palletizers for unconventional products

- Single and multi-lane palletizers

- Cobot palletizers

Custom Solutions

Have a complex application that you haven’t been able to find a solution for? Those are the types of challenges that our skilled engineers and programmers geek out over. They’re up for the challenge and are ready to demonstrate their innovation and out-of-the-box thinking. Learn more about our approach to tackling the toughest automation challenges.

Trusted Robot Distributor

QComp is a trusted distributor of ABB and FANUC industrial robots, offering direct robot sales to manufacturers, OEMs, and integrators. Whether you're building your own system or expanding an existing one, we can ship you a robot directly—no integration required.

Looking for more than just a sale? QComp can also be your long-term partner for robot maintenance, service, and support, helping you get the most from your investment over the life of your equipment.

.png?width=419&height=419&name=logo%20image%20(423%20x%20423%20px).png)

Contact Us

We’re up for the challenge! Complete the form below and we’ll be in touch soon.

Latest QComp News

Before You Sign a Contract: 5 Smart Questions to Ask an Automation Partner

Before signing an automation contract, ask these 5 smart questions to ensure safety, reliability, and long-term ROI from your robotics partner.

Two Robotic Integrations That ALMOST Went Wrong

See how QComp engineers solved unexpected robotic integration challenges with smart fixes that boosted reliability and efficiency.

More Than Integration: QComp Delivers Robot Parts, Service & Direct Sales

QComp is a trusted source for OEM robot parts, expert service, and direct robot sales from ABB, FANUC, and Stäubli.