Overcoming the Limitations of Robotic Arms with Vacuum Grippers

Vacuum grippers are commonly used in robotic automation for picking and packing lightweight and uniform boxes or flat plastic packaging. This type of material handling is relatively simple to perform.

But what happens when a robotic arm needs to pick and place a bag of frozen chicken wings that’s neither uniform nor flat and might even have surface moisture? Or a production line filled with porous water filters that are oddly shaped?

As versatile and capable as vacuum grippers are, they have their limitations. So, how do robotic engineers design robotic cells to overcome these challenges?

What Are Vacuum Grippers?

To start, let’s define vacuum grippers and how they work.

Vacuum grippers are attached to the end of a robotic arm to pick up and move products to a production line, Gaylord rack, shipping boxes, or other locations. Vacuum technology works by moving air, creating a pressure differential between two surfaces — the suction cups and the object’s surface. When the differential is great enough, it creates a seal to join them together.

Typically, a vacuum pump or generator removes the air from the system to create the seal. The greater the pressure and the larger the surface area, the more holding capacity the vacuum seal will need.

There are different types of vacuum grippers, including:

- Suction cup grippers. These end-of-arm tools perform better with flatter and more rigid products. That said, there are numerous shapes and materials that a robotics integrator can test to get the results you need. Vacuum gripper materials might include regular silicone, food-grade silicone, rubber, or other substrates depending on the need

- Foam grippers. Foam grippers use a porous foam pad that allows it to conform to irregular surfaces. In essence, foam grippers are a continuous sheet of extremely small vacuum cups spread across a small or very large foam mat

The Pros & Cons of Vacuum Grippers

Vacuum grippers are arguably the most common type of end-of-arm tooling used in material handling, and for good reasons:

- Lower up-front costs. The cost to design and manufacture vacuum grippers is considerably lower than alternative end-of-arm tools. This is especially true for simple plate and cup designs that move objects with standard shapes and sizes

- Versatility. Vacuum can be used to pick a variety of product sizes when zoned properly. It is a proven technology that works well in many applications and industries. Vacuum technology can even be used in sanitary environments like direct food contact

- Fast changeover times. Cups usually can be changed out quickly if they become worn, so downtime is limited

- Safety. Vacuum technology has fewer moving parts, helping to minimize safety concerns

I’ve already hinted at the potential disadvantages of vacuum grippers, but let me expound:

- Higher operational costs. While upfront costs are cheaper, vacuum technology can be expensive to operate due to the high costs of generating compressed air. Vacuum blowers can be an alternative, but these units take up a large footprint and might only be able to handle one end-of-arm tool

- Noise. Vacuum tools can be noisy to operate

- Potential inconsistencies. When the vacuum is turned off to release a product, some products might stay attached to the tool. Likewise, some vacuum grippers need product stabilizers to support the product after it is attached to the tool to keep the product from shearing off the cups when in motion. Plus, porous, wet, or dirty products will not create a sufficient seal in some applications

- Indentations. Improperly designed vacuum grippers can leave marks on products

- Clogging. Vacuum ports can get clogged with debris causing poor performance, more maintenance, and production downtime. Bacterial growth can develop in vacuum lines if cleaning guidelines are not followed — especially important for the food industry

- Wear and tear. Movements of end-of-arm tools can cause cups to tear or fail, especially suction cups that are thin and pliable

Manufacturers need to weigh the pros and cons and work with an integrator who can thoroughly assess their needs and determine a custom solution.

How Robotics Engineers Tackle Complex Material Handling

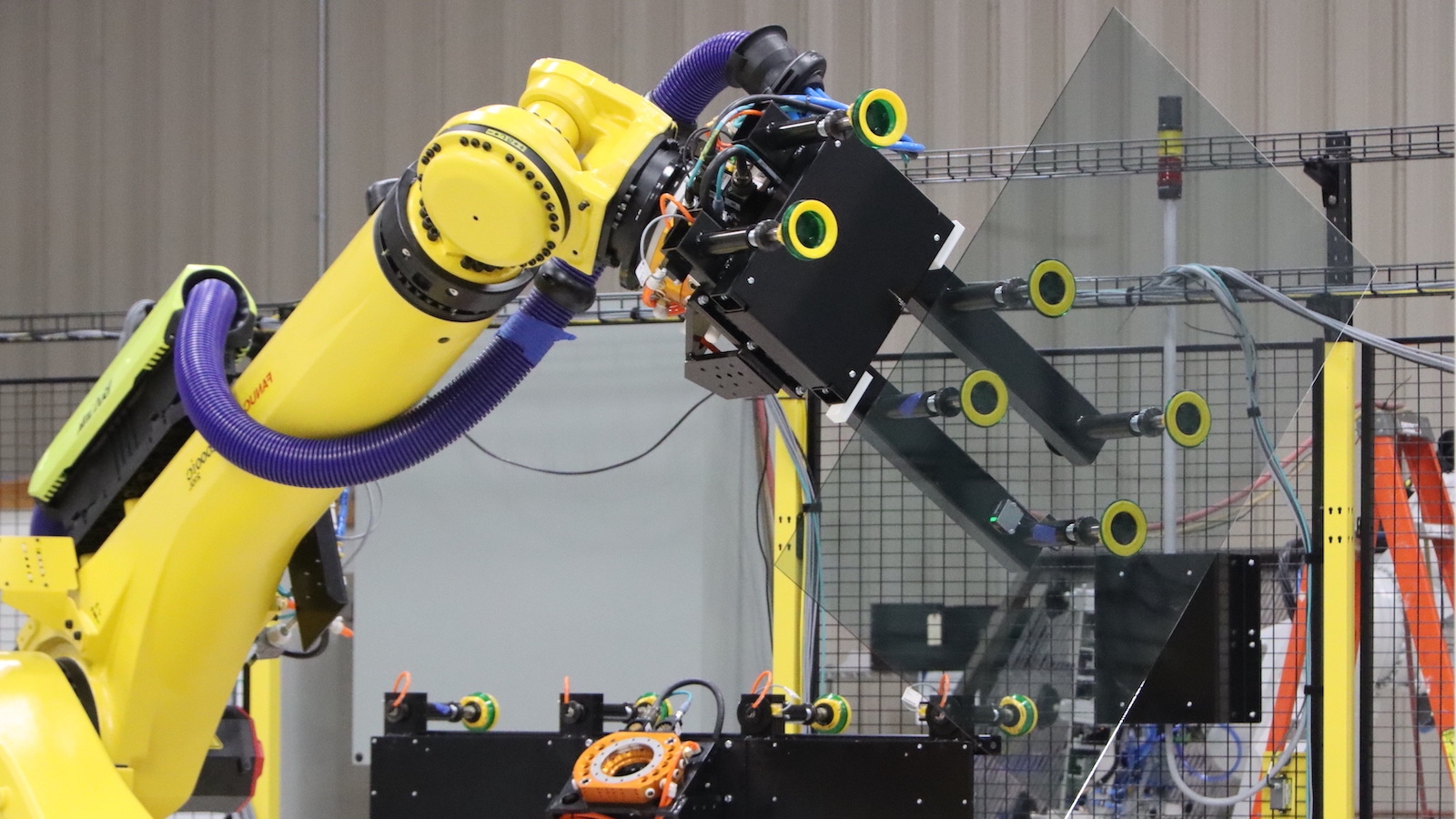

Here at QComp, we routinely use vacuum technology where appropriate. For example, we designed a way to pick up large pieces of glass using non-marking vacuum cups to place them in racks without breaking. This is a dangerous task once thought only possible with human hands, but we were able to design a solution.

While creating a seal on glass isn’t difficult, the various sizes and weights of more than 1,000 pounds were. Engineers had to extrapolate precise calculations to determine the exact number of cups required per square inch to accommodate various glass sizes and ensure that the cups weren’t cut when coming into contact with the edges of the glass. We also used zoning where only a designated number of suction cups are activated based on size and weight. These computations are critical for fragile glass because too much vacuum pressure could shatter it and not enough could drop it.

READ MORE → Jumbo Glass Robotic Rack Loading System

Another example is the type of bags used for lawn and leaf refuse. Laid flat, they couldn’t be picked up with vacuum grippers because they’re too porous. But folding them in an accordion style creates enough differential to grip them. Inconsistent products may require cups with bellows that allow one to reach farther than an adjacent cup to make up for irregularities.

When presented with such challenges, we first seek to fully understand the need, preferably visiting the facility to see the manufacturer’s current process for handling the materials. Then, we’ll assess the situation and collaborate with one of our robotics partners like Fanuc, Stäubli, or ABB.

If we determine that vacuum grippers aren’t the best solution, we’ll pursue an alternative type of gripper, such as:

- Mechanical grippers. These use side-clamping pressure to squeeze the product

- Soft grippers. Silicone finger appendages use air to open and close, moving similarly to human fingers to grip products

- Magnetic grippers. End-of-arm magnets lift ferrous metal materials

- Needle grippers. Used to hold products like sponges within end-of-arm tools

Soft grip technology works well to overcome products that do not hold their shape. For example, dough balls that have been covered in vegetable oil work best with silicone finger grippers because vacuum grippers simply won’t work. All that said, there often is no single solution. Sometimes, we’ll engineer more than one type of gripper into a robotic arm to transport a product.

Do you have a complex material handling challenge? Robotic capabilities have advanced significantly in recent years, so if you previously thought something wasn’t possible, it may be the right time to take another look. We’re up for the challenge. Contact the team at QComp to see how we conquer complexity and work with you to find a solution.

Share this

You May Also Like

QComp: Proud to Be One of the First ABB Value Providers in the World

QComp was the third company in the world to join ABB’s Value Provider Program. Discover how decades of partnership and proven expertise help us deliver smarter, certified automation solutions that conquer complexity.

Improving Glass Industry Safety: How Automation Helps Prevent Injuries

How to improve safety in the glass manufacturing industry using robotic automation. Explore how a leading robotics integrator is solving the toughest challenges.

The Automation Advantage: Combat Labor Shortages and Win the Talent War

Discover how automation can help manufacturers tackle labor shortages, improve safety, and achieve a positive ROI in this insightful blog post conversation between industry experts.