Cable Management in Glass Line Automation: An Overlooked Necessity

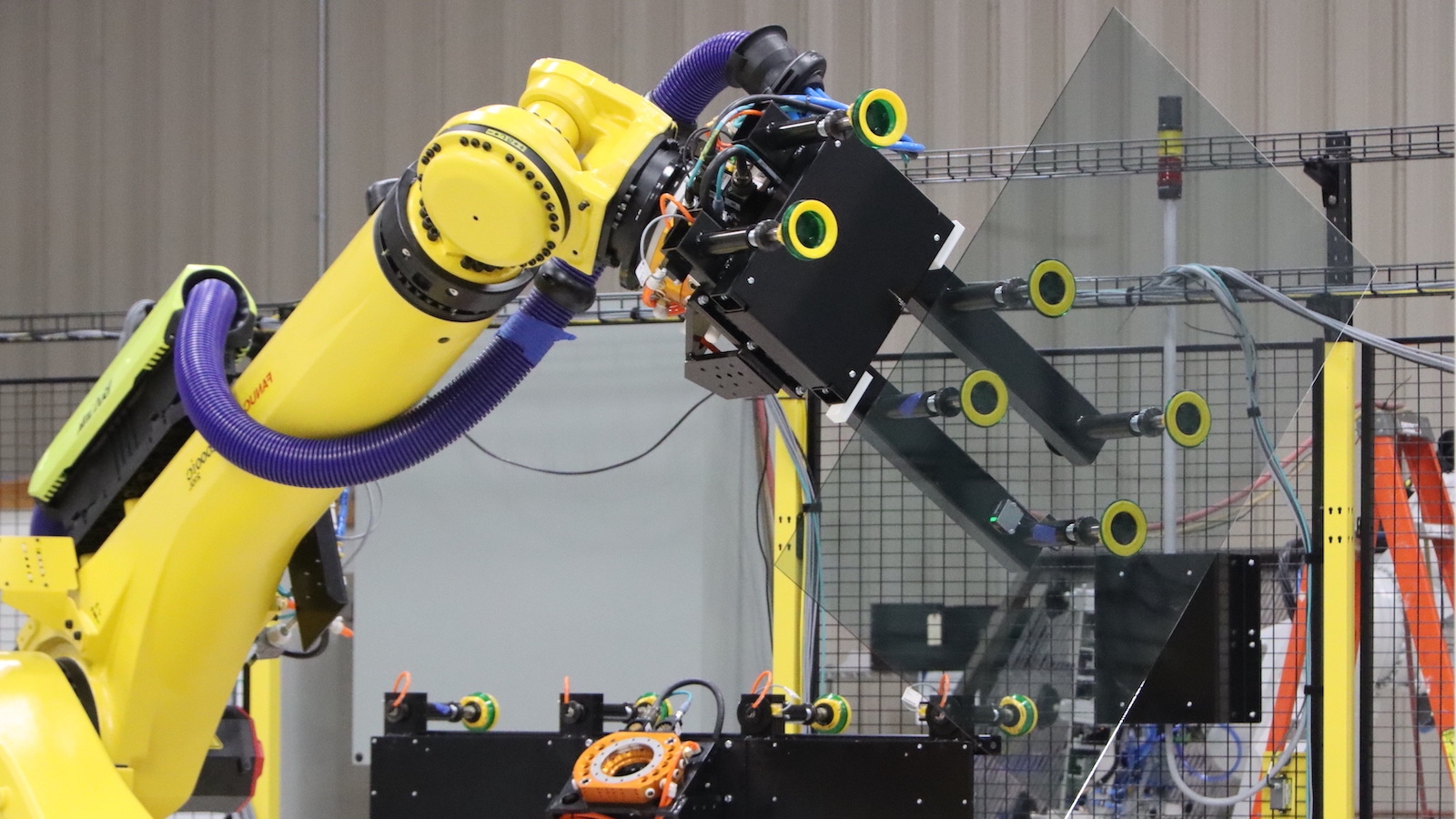

Uptime is everything in glass manufacturing. Equipment failure can ripple through operations, leading to lost production and revenue, safety concerns, defective or broken products, and frustrated clients. Robotic systems in the glass industry rely heavily on end-of-arm tooling and vacuum grippers to minimize these risks, loading or unloading large panels of glass during various phases of production.

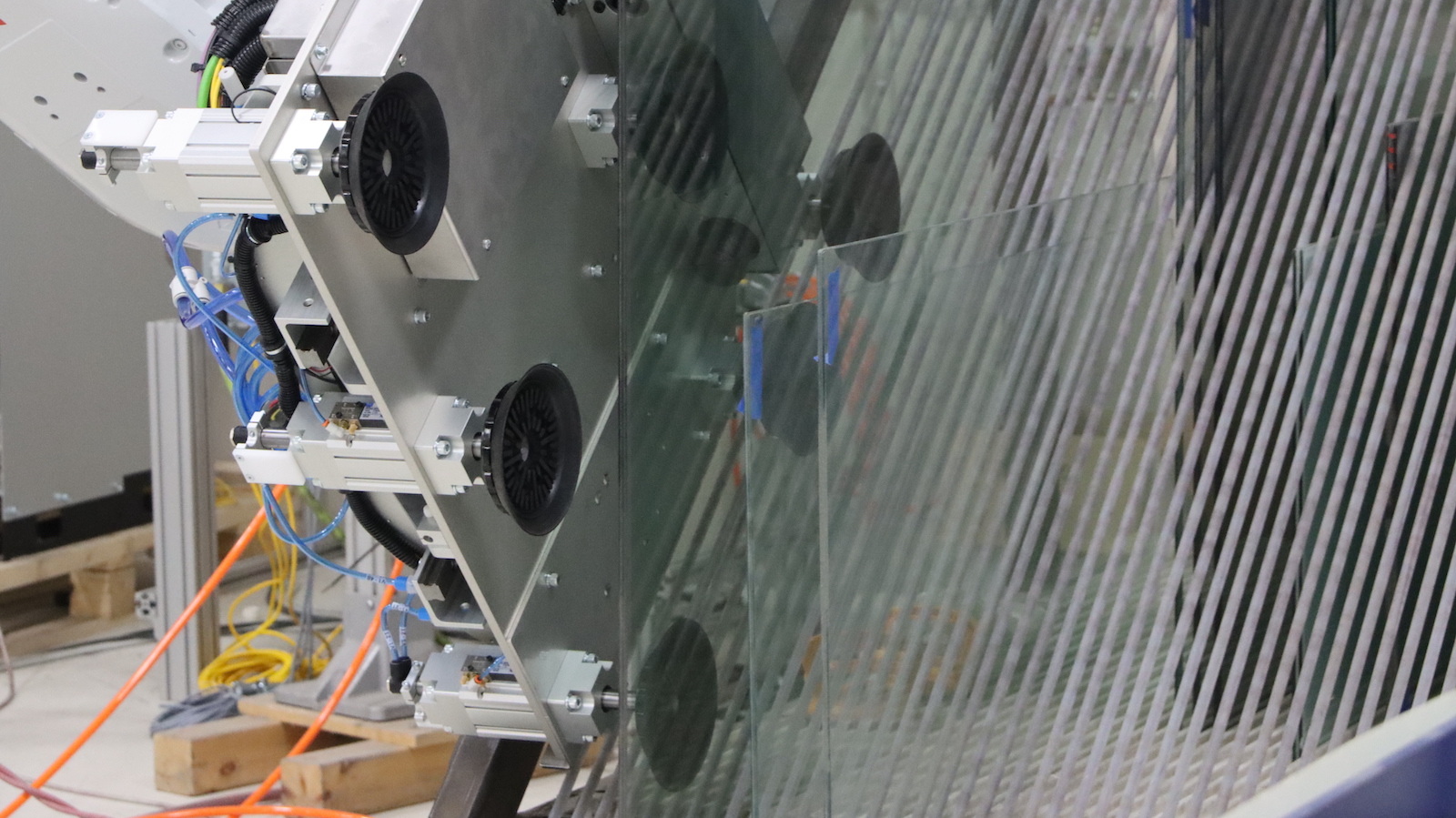

Designing a robotic arm with vacuum grippers involves much more than precise engineering, however. One of the most overlooked yet critical vulnerabilities in robotic systems is protecting and managing the cables and pneumatic hoses as part of the vacuum system.

QComp partnered with BizLink, a leading cable management company, to engineer a unique solution.

GET THE GUIDE: Improve Safety & Efficiency in Glass Automation

The Fragility Challenge in Glass Production

For manufacturers dealing with large, delicate glass panels, robotic components are exposed to harsh environments that threaten both performance and longevity.

Glass production facilities pose unique challenges for robotic equipment. Panels range from 20-inch squares to massive 72x96-inch sheets, often weighing hundreds of pounds each. The edges are sharp, and the manufacturing process creates a demanding environment with dust, debris, and tight spatial constraints. Without robotic automation, multiple people would be required to lift and move large pieces of glass onto harp racks or other production areas, posing unnecessary safety risks.

Another challenge is the multiple angles at which a robot must pick the glass, both from above or below the infeed conveyor. Robots tasked with lifting, moving, and stacking these panels must operate with precision, agility, and speed.

LEARN MORE: Automated Flat Glass Handling

As the tool articulates to pick or place the glass, cables and hoses have to extend and retract to follow the tool’s motions. The power supply is a critical yet sometimes underappreciated component of a robotic system, and the multiple angles at which a piece of glass might be positioned pose a risk of coming into contact with the cable system. Robotic cables must also withstand high acceleration and deceleration, stress, compression, abrasion, and torsion, not to mention millions of bending cycles and potential thermal exposure.

Where there’s glass, there are sharp edges. One false move of a robot and the pneumatic hoses and electrical wires could be severed and send glass shattering to the ground, highlighting the importance of precision robotics combined with smart cable routing and management. Cabling assemblies must be insulated and protected while remaining flexible and agile.

Cable Management for Uninterrupted Operations

Recognizing these pain points, QComp’s robotic engineers partnered with BizLink to develop a customized cable management solution that withstands the rigors of glass production lines while ensuring uninterrupted operation.

Traditionally, hoses and cables are left to hang down or swing below the main parts of the robot, exposing them to potential risks. The durable cable management solution designed by QComp and BizLink incorporates pre-engineered components tailored to the unique needs of glass-handling robots. Key features include:

- Integrated Retract Mechanism: This keeps cable slack to a minimum, ensuring the hoses and wires move with the robot’s motions without tangling or dragging

- Durable Outer Shells and Conduits: These durable components shield cables from sharp glass edges, dust, debris, and other harsh production environments

- Compact Design: The system’s streamlined profile fits within limited spaces, allowing robots to maneuver efficiently without excess bulk

- Mounting Ingenuity: QComp and Bizlink collaborated to design a solution that could be mounted on top of a Fanuc robot or adapted to mount to the side, mitigating interference and improving agility.

Collaboration is what made the partnership work and, ultimately, made the robotic solution work. “QComp’s team is always a pleasure to work with—they have true professionals in all roles,” said Blake Mattingly, Technical Sales & Account Manager for BizLink. “I believe that we share many of the same values and attributes. Prompt and precise communication, fantastic B2B collaboration, and well thought-out project management.”

Engineered for Uptime & Scalability

An important part of implementing a robotic solution is rapid installation and reliability. 3D modeling aids in the design and implementation, allowing engineers to envision the technology more clearly. Because the cabling systems and pneumatic hose placement are engineered in conjunction with the development of the robotic cell, the setup is simplified. This allows QComp’s robotic systems to integrate seamlessly into existing production lines.

Setup and installation aren’t the only efficiencies gained. By reducing installation time and minimizing the risk of damage during operation, glass manufacturers can ramp up production more quickly and achieve higher uptime and lower maintenance costs.

The system is designed for scalability to accommodate various sizes of glass panels and growing production volumes. The robotic tooling and cable management system ensures the robotic equipment can adapt without compromising performance or durability.

A Durable Future for Glass Manufacturers

By proactively addressing the challenges of cable management, QComp has set a new standard for robotic systems in the glass manufacturing industry. Their partnership with BizLink highlights the importance of collaboration to protect the often-overlooked components that power advanced automation.

Precision, safety, and uptime are non-negotiable in the glass industry, and the combination of robotic ingenuity and a robust cable management system provides a clear advantage. It’s not just about keeping the lines moving—it’s about redefining what’s possible in glass production and keeping workers safe.

Learn more about glass automation and robotic solutions in our industry resource, Improve Safety and Efficiency in Glass Manufacturing with Robotics. Download this helpful guide today.

Share this

You May Also Like

Automation Challenge: Glass Industry Harp Rack Loading

Learn how QComp’s innovative harp rack unloading automation improves glass industry safety, reduces risks, and boosts precision and productivity.

Optimizing Glass Line Load and Unload with Robotic Automation

Robotic glass line load/unload automation improves safety, efficiency, and productivity. Discover robotic solutions to optimize handling in glass manufacturing.

Improving Glass Industry Safety: How Automation Helps Prevent Injuries

How to improve safety in the glass manufacturing industry using robotic automation. Explore how a leading robotics integrator is solving the toughest challenges.